It's Christmas Eve, and ever since I found the Santa hat in our decorations the other day, I have been wearing it. It's been kind of cool lately and the new workshop needs to be a little warmer. It's all insulated, so when it gets warm, it stays that way. But I have to heat it with a little propane heater, and with no ventilation, I have to leave the door open a crack and pretend its not hurting me.

I have been very busy lately doing the final drawings for the telescope and actually cutting and assembling the parts for the rig that holds the main mirror (the mirror cell in ATM parlance). I have become a huge fan of J-B Weld epoxy. When the design I made called for a screw that no one actually makes, I made one from a small socket head screw (for the head) a 3/4" piece of brass tube and some 5/16"-18 threaded rod. Strong like bull.

The rest of the design is simply 1" square aluminum tubing that I cut with the table saw and a newly sharpened carbide blade.

I made up a gluing jig from some wood scraps I had laying around and clamped it all together with the J-B Weld.

We have to go out in a little while to Dave and Emily's. Their boys got a little Tasco telescope for Christmas and they want me to tell them how to use it....... "First, get a clear night"... Dark and stormy here today and tomorrow.

Anyway, to the pictures.

This is the crossbar. Without getting into a lot of detail, these are two of the four points for the flotation system. Those are t-nuts held on with 1/2" hex bolts cut down to fit and glued with J-B Weld.

Here it is at the top inserted into its slot. The rest of the parts are all clamped and glued into place on the jig.

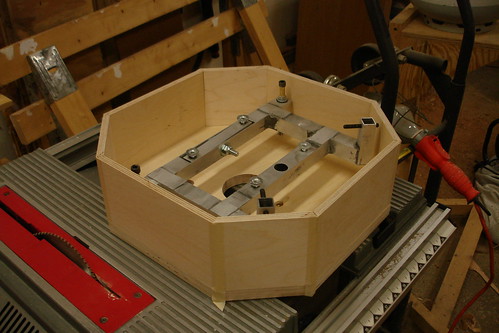

Here is the top shot of the cell in the jig. to the right are the adjustment screws I made.

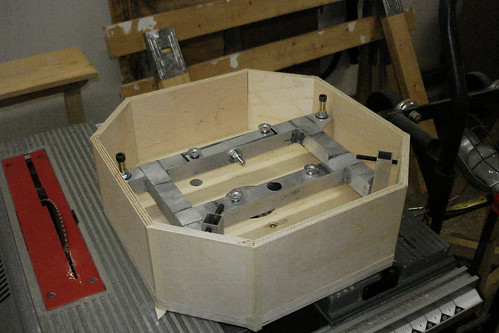

From the side.

Here are the three adjustment screws. A short 5/16"-18 x 1/2" socket head cap screw glued into one end of a 3/4" long brass tube. Into the other end is threaded rod. This gives a short shank under the head. Everything else available anywhere only had 1 1/2" of thread. (I looked in McMaster-Carr, Small Parts, and even the old fashioned Handy Ace hardware in Tucker (if its made, they have one). No one had a fully threaded 3 1/2" x 5/16" socket head cap screw or even a hex head bolt. Not even something close in metric. Had to make my own. I had problems getting the barrel, screw and rod lined up while the glue set. I'm still not satisfied. I will likely ask my ATM buddies for ideas.

Next time, the finished cell!